Shamrock Precision: Swiss Machining Excellence for Aerospace and Defense

Modern aircraft contain miles of electrical wiring routing power and signals to every system from cockpit avionics to landing gear sensors. Protecting this complex network from heat, abrasion, vibration, and electromagnetic interference requires precision-manufactured sleeve conduits designed for the specific environmental challenges found throughout aircraft structures. Manufacturing these critical protection components demands machining capabilities that consistently deliver tight tolerances while working with aerospace-grade materials under the rigorous quality requirements that aviation safety demands.

Sleeve conduits serve as the protective backbone of aircraft electrical wiring interconnection systems. The Federal Aviation Administration maintains comprehensive manufacturing best practices for aerospace components, emphasizing that production processes must ensure consistent quality and regulatory compliance across all flight-critical hardware. These best practice documents have been developed and provided by the FAA and aerospace industry manufacturers, with each document reviewed by the Aircraft Certification Service for content relevance, compatibility with regulatory requirements, and appropriateness to the broad range of aerospace manufacturers.

Federal regulations require that electrical wiring be designed and installed with adequate physical separation from other aircraft components and protected from sharp edges and corners to minimize potential for abrasion and vibration damage. The precision of sleeve conduit manufacturing directly impacts whether installed wiring systems meet these stringent safety requirements throughout decades of operational service spanning hundreds of thousands of flight hours and countless pressurization cycles.

The manufacturing challenges for aerospace sleeve conduits extend beyond simple dimensional accuracy into areas that determine long-term reliability and safety. Wall thickness uniformity affects both protection capability and installed weight, making consistent machining critical for components installed throughout aircraft structures where every gram contributes to fuel consumption over aircraft service life. Internal surface finish quality determines whether wiring can be pulled through conduits without insulation damage during installation and maintenance operations that occur throughout aircraft operational service. Thread engagement on end fittings must meet exacting specifications to ensure secure connections in high-vibration environments where loosening creates immediate safety concerns.

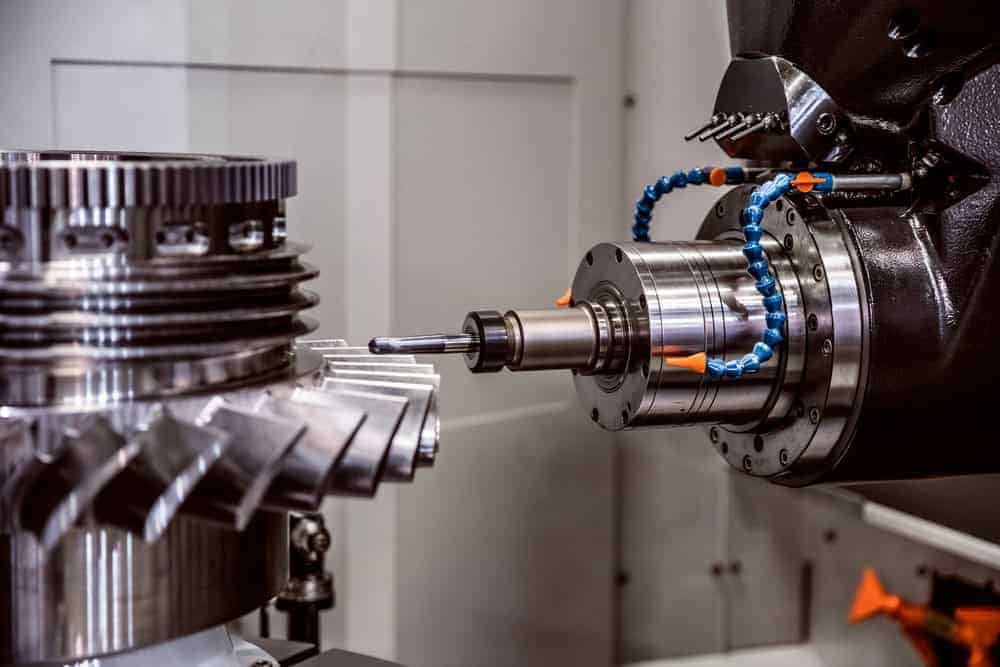

Swiss machining addresses these requirements through manufacturing principles specifically suited to tubular precision components with demanding geometric requirements. The guide bushing support system positions cutting tools extremely close to the workpiece during material removal, eliminating the deflection that creates wall thickness variation in conventional turning operations where workpiece overhang from the spindle introduces bending forces. Multi-axis capability enables complex threading, grooving, and finishing operations in single setups, maintaining concentricity relationships that would drift across multiple operations and setups on standard equipment.

Understanding broader aerospace supply chain dynamics helps contextualize the critical role precision components play in aviation safety and industry economics. Exploring Aerospace Swiss Machining: Meeting Demand for Critical Electrical Components provides essential context for how Swiss machining capabilities support electrical system manufacturing across multiple component categories serving aircraft programs throughout commercial and defense sectors.

Material selection for sleeve conduits depends on installation location and environmental exposure throughout the aircraft structure. Engine nacelle applications may require nickel-based superalloys including Inconel 625 or 718 capable of withstanding temperatures exceeding 1000°F while maintaining structural integrity and corrosion resistance in aggressive chemical environments. Wing and fuselage installations typically utilize aluminum alloys optimized for corrosion resistance and weight efficiency, with 6061-T6 and 7075-T6 representing common selections depending on strength requirements. Each material presents distinct machining challenges that experienced aerospace shops navigate through proven process parameters developed over thousands of production hours working with specific alloy compositions.

The National Institute of Standards and Technology emphasizes that aerospace manufacturing requires precision measurements of many quantities including length when assembling and installing critical components. Current high-end instruments for measuring based on laser wavelength can be bulky and require time-consuming calibrations of costly equipment. NIST is working on mass-producible, inexpensive chip-scale devices to provide wavelength reference standards for those calibrations, relying on the fact that the international standard for the meter is based on the distance that light travels in a fraction of a second.

Documentation requirements extend from raw material certification through final inspection, creating the traceability records aerospace customers require for every delivered component. Material test reports verify alloy composition and mechanical properties. Process documentation demonstrates that manufacturing occurred under controlled conditions using qualified procedures. Dimensional inspection records prove that finished components meet all drawing requirements. This documentation accompanies every shipment, providing the evidence trail that supports airworthiness determinations throughout aircraft service life.

Quality verification for sleeve conduits involves both dimensional inspection and functional testing that confirms manufactured components will perform as intended in service. Thread gauges verify engagement characteristics ensuring secure connections under vibration loading. Concentricity measurements confirm that wall thickness remains uniform around the circumference, preventing weak spots that could fail under pressure or mechanical stress. Surface finish assessment ensures internal surfaces meet specifications for wire installation without insulation damage that could create electrical faults. Visual inspection identifies any machining artifacts that could create stress concentration points or contamination risks in sensitive applications.

Production volumes for sleeve conduits range from prototype quantities during aircraft development phases requiring dozens of components for flight test articles to thousands of components monthly for mature production programs building aircraft at rate. The machining flexibility offered by Swiss equipment accommodates both scenarios effectively, with rapid program changeovers enabling economical small-lot production while automated bar feeding systems support extended unattended operation for volume requirements that demand manufacturing efficiency.

The thin-wall geometry common to sleeve conduits creates machining challenges that conventional equipment handles poorly. Wall sections measuring fractions of an inch thick deflect under cutting forces, creating chatter marks, dimensional variation, and surface finish degradation that renders parts unusable. Swiss machining eliminates these problems through the guide bushing support system that positions material rigidly during cutting regardless of wall thickness or length-to-diameter ratios that would be impossible to machine conventionally.

For aerospace procurement professionals evaluating manufacturing partners for electrical protection components, examining Precision Mounting Sleeves and Inserts: Swiss Machining for Aerospace Structural Applications reveals how Swiss machining capabilities extend across related component families requiring similar precision levels and quality documentation infrastructure.

The convergence of supply chain pressures and increasing electrical system complexity in modern aircraft creates sustained demand for qualified sleeve conduit manufacturers who can deliver consistent quality on demanding schedules. Shops combining Swiss machining capability with aerospace certification and documented production experience position themselves as reliable supply chain partners for programs demanding consistent quality delivery throughout extended production runs spanning years of aircraft manufacturing.

Shamrock Precision: Your Partner in Aerospace Manufacturing Excellence

At Shamrock Precision, we manufacture precision sleeve conduits meeting aerospace specifications through AS9100-certified Swiss machining processes. Our team understands the critical role these components play in protecting aircraft electrical systems throughout operational service spanning decades of flight operations.

Our Services Include:

- Aerospace Machining Services - Swiss CNC production of sleeve conduits with wall thickness control to ±0.001 inches

- Contact Us - Request quotations for your sleeve conduit manufacturing requirements

Works Cited

"Manufacturing Best Practices." Federal Aviation Administration, U.S. Department of Transportation, 3 Apr. 2025, www.faa.gov/aircraft/air_cert/production_approvals/mfg_best_practice. Accessed 1 Feb. 2026.

"Aerospace." National Institute of Standards and Technology, U.S. Department of Commerce, 13 Aug. 2025, www.nist.gov/noac/industries/aerospace. Accessed 1 Feb. 2026.

Related Articles

- Aerospace Swiss Machining: Meeting Demand for Critical Electrical Components

- Precision Mounting Sleeves and Inserts: Swiss Machining for Aerospace Structural Applications