Shamrock Precision: Swiss Machining Excellence for Aerospace and Defense

The aerospace industry confronts a manufacturing crisis that threatens production timelines across commercial and defense sectors. Supply chain bottlenecks have created delivery shortfalls totaling at least 5,300 aircraft, while component backlogs now exceed 17,000 units representing nearly twelve years of current production capacity. For manufacturers producing precision electrical system components including sleeve conduits, mounting sleeves, and inserts, the pressure to deliver flight-ready parts has never been greater.

Aerospace electrical wiring interconnection systems represent one of aviation's most demanding manufacturing challenges. Every aircraft relies on thousands of precision-machined components to protect, route, and secure the electrical wiring that powers critical flight systems. These parts must withstand extreme temperatures, constant vibration, and rapid altitude changes while maintaining tolerances measured in ten-thousandths of an inch. The complexity of modern aircraft electrical architectures continues expanding as manufacturers incorporate more sophisticated avionics, fly-by-wire controls, and integrated sensor networks throughout airframe structures.

According to the Aerospace Industries Association, the U.S. aerospace and defense industry generated over $995 billion in total business activity in 2024, with more than 2.2 million workers employed across direct and indirect roles. The industry contributed $443 billion in economic value while maintaining a $73.86 billion trade surplus that continues outperforming other manufacturing sectors. This economic dominance depends entirely on manufacturers capable of producing components that meet aerospace-grade specifications consistently and delivering them on schedules that support production rate increases across major aircraft programs.

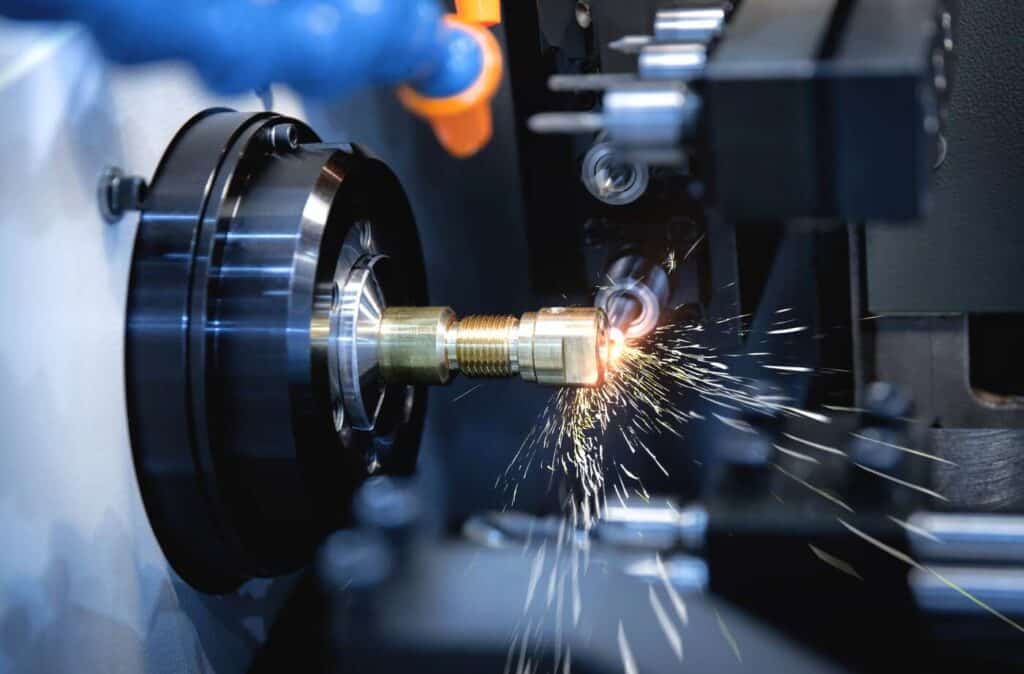

Swiss machining has emerged as the manufacturing method of choice for producing complex aerospace electrical components. Unlike conventional CNC turning, Swiss-type machines support the workpiece extremely close to the cutting tool through a guide bushing system. This configuration dramatically reduces deflection and vibration during machining, enabling tolerances as tight as ±0.0005 inches on small-diameter components that would be impossible to achieve consistently with standard equipment. For sleeve conduits and mounting hardware that protect sensitive wiring throughout aircraft structures, this precision level directly impacts flight safety and long-term reliability.

The demand for specialized machining capacity continues outpacing supply across the aerospace sector. Supply chain pressures cascade throughout the industry, creating urgent demand for machine shops capable of producing precision electrical components without compromising quality or delivery schedules. Manufacturers who invested in Swiss machining capability and maintained aerospace certifications through recent industry disruptions now find themselves positioned to capture significant market share as production rates accelerate across commercial and defense programs.

Understanding the specific manufacturing challenges for individual component types helps aerospace procurement teams identify capable suppliers who can deliver consistent quality across extended production runs. Examining Aerospace Sleeve Conduits: How Swiss Machining Protects Critical Wiring Systems reveals the technical requirements for producing conduit components that shield electrical harnesses from environmental hazards encountered throughout aircraft operational envelopes.

Material selection compounds manufacturing complexity for aerospace electrical components in ways that general industrial machining never encounters. Sleeve conduits and mounting sleeves often require exotic alloys including various grades of aluminum ranging from 2024-T351 to 7075-T6, stainless steel grades including 303, 304, and 17-4 PH, and nickel-based superalloys like Inconel 625 and 718 depending on temperature requirements and installation locations. Each material demands specific cutting speeds, feed rates, coolant strategies, and tooling selections that only experienced aerospace machine shops understand through years of production experience working with these demanding specifications.

Quality system requirements add another critical dimension to aerospace component manufacturing that separates qualified suppliers from shops simply claiming capability. AS9100 certification has become the universal gatekeeper for aerospace supply chain participation, building on ISO 9001 foundations with aerospace-specific requirements for risk management, traceability, configuration control, and counterfeit parts prevention. Major aerospace OEMs including Boeing, Lockheed Martin, and Northrop Grumman require AS9100 compliance as a baseline condition for doing business, making certification essential for any machine shop seriously targeting this market. The certification process requires documented quality management systems, trained personnel, calibrated equipment, and demonstrated process capability that takes years to develop properly.

The economic stakes for aerospace manufacturers extend beyond individual contracts to long-term supply chain positioning. With average labor income per aerospace job reaching $115,000 according to industry data, these positions represent significant economic opportunity for manufacturing regions. Machine shops that establish themselves as reliable aerospace suppliers gain access to programs spanning decades of production requirements, creating stable revenue streams that support continued investment in capability and workforce development.

For machine shops pursuing aerospace work, understanding Precision Mounting Sleeves and Inserts: Swiss Machining for Aerospace Structural Applications provides insight into the technical capabilities required to support aircraft structural assemblies where electrical systems interface with airframe components through precision mounting hardware.

Production volume requirements vary dramatically across aerospace programs, demanding manufacturing flexibility that Swiss machining uniquely provides. Development and prototype phases may require only dozens of components for flight test articles, while mature production programs demand thousands of identical parts delivered on aggressive schedules synchronized with aircraft assembly operations. Swiss machining accommodates both scenarios through automated bar feeding systems enabling lights-out operation for volume production combined with rapid changeover capabilities that make small-lot specialty work economically viable without extended setup charges.

The International Air Transport Association reports that supply chain bottlenecks will cost airlines more than $11 billion in 2025 through excess fuel costs, additional maintenance expenses, increased leasing costs, and surplus inventory requirements. A shortage of skilled labor, especially in engine and component manufacturing, constrains production ramp-up plans across the industry. The fragility of the aerospace supply chain network, often reliant on a limited number of suppliers for critical parts, becomes an acute constraint amid economic uncertainty and tight labor markets.

The technical advantages of Swiss machining translate directly to quality and cost benefits for aerospace electrical components. Reduced deflection enables tighter tolerances without secondary operations. Multi-axis capability completes complex features in single setups, maintaining geometric relationships that would drift across multiple operations. Automated operation reduces labor content while improving consistency. These manufacturing efficiencies compound across production volumes, creating cost advantages that make Swiss-machined components competitive despite the demanding quality requirements aerospace customers impose.

Documentation requirements for aerospace components create administrative burdens that unprepared suppliers find overwhelming. First article inspection reports establishing process capability. Material certifications tracing alloy composition back to mill sources. Process certifications demonstrating operator qualifications and equipment calibration status. Certificates of conformance attesting that delivered components meet all drawing requirements. This documentation infrastructure requires dedicated quality personnel and established procedures that take years to develop and refine through customer feedback and audit findings.

The path forward for aerospace manufacturers requires partnering with machine shops that combine technical capability with genuine industry expertise developed through years of production experience. Understanding aerospace expectations, maintaining appropriate certifications, investing in quality infrastructure, and delivering documented quality on every component separates qualified suppliers from shops that will ultimately fail to meet program requirements when pressures intensify during production rate increases.

Shamrock Precision: Your Partner in Aerospace Manufacturing Excellence

At Shamrock Precision, we deliver AS9100-certified Swiss machining services specifically designed for aerospace and defense applications. Our experienced team understands the critical requirements for electrical system components including sleeve conduits, mounting sleeves, and inserts that protect aircraft wiring systems throughout operational service.

Our Services Include:

- Aerospace Machining Services - Precision Swiss CNC machining with tolerances to ±0.0005 inches for flight-critical components

- Contact Us - Discuss your aerospace component requirements with our engineering team

Works Cited

"2025 Facts & Figures: American Aerospace & Defense Industry Continues Economic Dominance." Aerospace Industries Association, 17 June 2025, www.aia-aerospace.org/news/american-aerospace-defense-industry-continues-economic-dominance/. Accessed 1 Feb. 2026.

"Aerospace Supply Chain Bottlenecks Continue to Constrain Airlines." International Air Transport Association, 9 Dec. 2025, www.iata.org/en/pressroom/2025-releases/2025-12-09-02. Accessed 1 Feb. 2026.

Related Articles

- Aerospace Sleeve Conduits: How Swiss Machining Protects Critical Wiring Systems

- Precision Mounting Sleeves and Inserts: Swiss Machining for Aerospace Structural Applications