Failing to conduct a thorough tolerance stackup analysis in manufacturing creates quality disasters that extend far beyond individual component rejection. These precision failures trigger cascading effects that compromise assembly function, increase production costs, and damage customer relationships throughout the supply chain.

Knowledge of tolerance control principles helps manufacturing teams implement systematic approaches that prevent quality problems and reduce production costs. At Shamrock Precision, our Swiss machining services provide the precision control and consistency required for critical tolerance applications across multiple industries.

Tolerance Stack up Disasters in Assembly Operations

Complex assemblies require multiple components to fit together with precise dimensional relationships. When individual component tolerances stack up unfavorably, assembly problems occur that prevent proper fit and function. Utilizing a high-performance swiss machine shop can mitigate these risks by ensuring each part remains within a tight, repeatable range.

Worst-case tolerance stack up occurs when all component dimensions fall at tolerance extremes in the same direction. Statistical probability makes this unlikely, but when it occurs, assemblies may not fit together or may fail functional requirements. Design teams must analyze worst-case scenarios to prevent assembly problems.

While statistical tolerance analysis provides a more realistic assessment of assembly variation, the root of success lies in the execution. Advanced CNC swiss machining services allow for the simultaneous control of multiple features, significantly reducing the probability of a "worst-case" stack up during the assembly phase.

Geometric dimensioning and tolerancing principles control form, fit, and function more effectively than traditional plus-minus tolerancing. GD&T specifications define functional requirements directly rather than controlling individual dimensions independently. Proper GD&T application reduces tolerance stack up problems and improves assembly function.

Measurement uncertainty affects tolerance verification and can create false acceptance or rejection of components. Measurement systems must have adequate resolution and accuracy to verify component conformance to specifications. Inadequate measurement capability creates quality problems that may not be discovered until assembly or field operation.

Supplier capability variations across multiple vendors create tolerance control challenges when components from different suppliers must work together. Each supplier has different process capabilities and quality control systems that affect dimensional consistency. Supplier qualification and ongoing monitoring ensure consistent quality across the supply base.

Machining Process Capability Limitations

Manufacturing processes have inherent capability limitations that affect their ability to produce parts within specified tolerances. Process capability analysis identifies whether processes can consistently produce acceptable parts and highlights areas requiring improvement.

Machine tool accuracy affects the precision of machined components. Spindle runout, way wear, and thermal growth create systematic errors that affect dimensional accuracy. Regular machine calibration and maintenance are essential for any swiss CNC machine to maintain accuracy within acceptable limits for precision work.

Tool wear progression causes gradual dimensional changes during production runs. Cutting tools gradually wear and create dimensional drift that may cause parts to exceed tolerance limits. Tool life optimization and systematic tool replacement prevent tolerance violations from tool wear.

Setup variation between jobs creates dimensional differences when parts are machined in different setups. Fixture positioning, tool length variation, and work coordinate system errors affect dimensional consistency. Standardized setup procedures and verification methods reduce setup-related variation.

Environmental effects on machining accuracy include temperature variation, vibration, and humidity changes. Thermal expansion of machines and workpieces affects dimensional accuracy throughout the day and across seasons. Environmental control and thermal compensation systems maintain accuracy under varying conditions.

Process monitoring systems detect dimensional drift and process changes before parts exceed tolerance limits. Statistical process control charts identify trends and variations that indicate developing problems. Real-time monitoring and statistical process control (SPC) charts help identify trends before parts exceed tolerance limits, reducing scrap and ensuring swiss machining services remain cost-effective.

Learn more about precision machining capabilities in our detailed analysis of understanding precision machining definition, benefits and applications.

Material Property Variations and Their Impact

Material properties affect machining behavior and dimensional stability, creating challenges for maintaining tight tolerances. Property variations between material lots and within individual pieces affect machining consistency and dimensional control.

Hardness variations affect cutting forces and tool wear rates during machining. Harder materials require more cutting force and cause faster tool wear, affecting dimensional accuracy and surface finish. Consistent material quality and specialized CNC swiss machining services are required to account for these variables, ensuring that even exotic alloys meet design specifications.

Thermal expansion coefficients determine how much parts grow or shrink with temperature changes. Materials with high expansion coefficients require temperature control during machining and measurement to maintain dimensional accuracy. Thermal compensation systems account for expansion effects.

Internal stress in materials causes dimensional changes when stress is relieved during machining. Bar stock, forgings, and castings may contain residual stress that causes distortion when material is removed. Stress relief procedures and machining strategies minimize distortion effects.

Material composition variations affect machining characteristics and dimensional stability. Alloy content variations change cutting forces, tool wear, and thermal expansion properties. Material certifications and incoming inspection verify composition consistency.

Grain structure and metallurgical condition affect machining behavior and dimensional stability. Heat treatment conditions, working history, and aging effects change material properties. Proper material specification and supplier control ensure consistent metallurgical properties.

Surface Finish Requirements and Tolerance Relationships

Surface finish and dimensional tolerances are interrelated characteristics that affect both function and measurement. Poor surface finish can prevent accurate measurement and may affect assembly function even when dimensions are within tolerance.

To ensure quality, a top-tier swiss machine shop must monitor surface roughness, as it creates uncertainty in measured dimensions. Rough surfaces have peaks and valleys that affect probe contact and measurement repeatability. Specified surface finish requirements ensure measurement accuracy for critical dimensions.

Geometric tolerances control surface form and orientation relative to datums and other features. Flatness, straightness, and perpendicularity tolerances ensure proper assembly function regardless of surface texture. Geometric control provides functional requirements that dimension-only tolerances cannot achieve.

Manufacturing process selection affects both dimensional capability and surface finish quality. Turning, milling, grinding, and finishing operations each produce characteristic surface textures and dimensional capabilities. Process selection must consider both tolerance and surface finish requirements.

Surface integrity includes subsurface properties such as residual stress, microhardness, and microstructure changes. Machining processes affect surface integrity through cutting forces, temperatures, and deformation. Surface integrity requirements may be critical for fatigue life and functional performance.

Measurement system capability must match these requirements, utilizing coordinate measuring machines and surface profilometers to verify that swiss precision machining standards are met. Measurement system selection ensures adequate capability for tolerance verification.

Quality Control System Deficiencies

Effective quality control systems prevent tolerance problems through systematic measurement, analysis, and corrective action. Inadequate quality systems allow problems to continue and multiply throughout production.

To avoid this, high-end swiss machining services implement measurement system analysis (MSA) to ensure repeatable results. Inadequate sampling may miss quality problems, whereas excessive sampling wastes resources without improving quality. Statistical sampling plans optimize inspection effort while maintaining quality assurance.

Measurement system analysis verifies that measurement equipment and procedures provide accurate and repeatable results. Gage repeatability and reproducibility studies identify measurement system problems that could mask quality issues. Regular MSA ensures measurement system capability.

Statistical process control (SPC) charts provide early warning of process changes before parts exceed limits, a standard practice for any swiss CNC machine operating at high precision. Control charts provide early warning of process changes before parts exceed tolerance limits. Proper chart interpretation and response procedures prevent quality problems.

Corrective action procedures ensure that quality problems are investigated and resolved systematically. Root cause analysis identifies underlying causes rather than symptoms, preventing problem recurrence. Effective corrective action systems prevent chronic quality problems.

Supplier quality systems ensure that purchased components meet tolerance requirements. Incoming inspection, supplier audits, and performance monitoring verify supplier capability and quality. Supplier development programs improve supplier performance and reduce quality problems.

Tolerance Analysis and Design Optimization

Systematic tolerance analysis during design phases prevents assembly problems and optimizes manufacturing costs. Proper analysis balances functional requirements with manufacturing capability and cost considerations.

Functional tolerance analysis identifies which dimensions actually affect assembly function and performance. Not all dimensions require tight tolerances. By partnering with a swiss machine shop early in the design phase, manufacturers can utilize Design for Manufacturing (DFM) principles to improve manufacturability while maintaining strict function.

Manufacturing cost analysis evaluates the cost impact of different tolerance requirements. Tighter tolerances generally increase manufacturing costs through slower processes, more capable equipment, and increased inspection requirements. Cost-benefit analysis optimizes tolerance allocation.

Design for manufacturing principles optimize designs for production capability and cost. DFM analysis identifies design features that create manufacturing challenges and suggests alternatives that maintain function while improving manufacturability. Early DFM analysis prevents costly design changes.

Tolerance synthesis calculates required component tolerances to achieve assembly requirements. Mathematical models relate component variations to assembly performance and optimize tolerance allocation. Synthesis tools help designers achieve functional requirements at minimum cost.

Sensitivity analysis identifies which component tolerances have the greatest impact on assembly performance. High-sensitivity dimensions require tighter control, whereas low-sensitivity dimensions may allow relaxed tolerances. Sensitivity analysis focuses attention on critical dimensions.

Advanced Manufacturing Technologies for Precision

Modern manufacturing technologies provide improved capability for maintaining tight tolerances and reducing variation. Advanced processes enable precision production that was previously impossible or economically unfeasible.

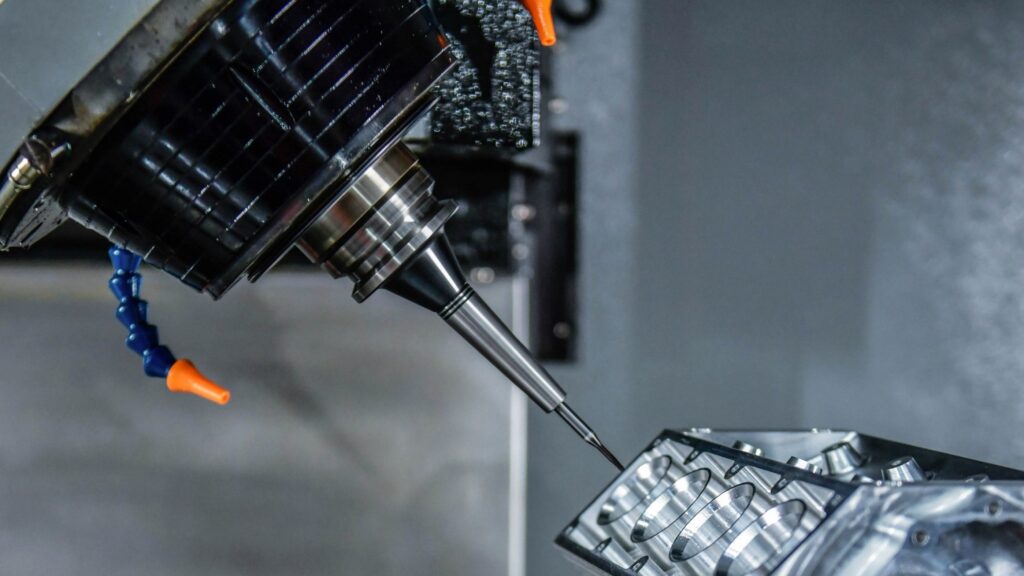

Multi-axis machining centers and the latest swiss CNC machine models provide improved accuracy by machining complex features in single setups. Five-axis and seven-axis machines eliminate setup errors and maintain better tool-to-work relationships for improved accuracy. Complex geometries can be machined to precise tolerances in single operations.

Adaptive control systems automatically adjust machining parameters to maintain dimensional accuracy as conditions change. Real-time measurement and feedback systems compensate for tool wear, thermal effects, and material variations. Adaptive control maintains consistent quality without operator intervention.

In-process measurement systems verify dimensions during machining and make corrections before parts are completed. Probing systems and laser measurement devices provide real-time dimensional feedback. In-process measurement prevents production of out-of-tolerance parts and reduces scrap.

These advanced CNC swiss machining services eliminate setup errors and positional drift, enabling the production of intricate geometries that were previously impossible to manufacture.

Precision grinding and finishing operations achieve surface finish and dimensional requirements that cannot be met by conventional machining. Grinding, honing, and lapping processes provide final accuracy and surface quality for critical applications. Finishing operations ensure functional requirements are met.

For comprehensive information on advanced manufacturing technologies, explore our insights on 5-axis machining for precision manufacturing.

Measurement and Inspection Strategies

Effective measurement strategies ensure that tolerance requirements are verified accurately and efficiently. Proper measurement planning optimizes inspection resources while maintaining quality assurance.

Coordinate measuring machine programming optimizes measurement efficiency and accuracy for complex parts. CMM programs can measure multiple features automatically and provide statistical analysis of results. Automated measurement reduces labor costs and improves measurement consistency.

Optical measurement systems provide non-contact measurement capability for delicate parts or complex geometries. Vision systems and laser scanners measure features that are difficult to access with contact probes. Optical systems provide rapid measurement for high-volume production.

Portable measurement devices enable measurement at production machines rather than in separate inspection areas. Portable CMMs, laser trackers, and handheld devices provide flexibility for large parts or in-process measurement. Portable systems reduce handling and provide immediate feedback.

Statistical analysis of measurement data identifies trends and patterns that indicate process changes. Control charts, capability studies, and correlation analysis provide insights into process performance. Statistical analysis helps optimize processes and prevent quality problems.

Professional swiss machining services rely on these strategies to provide immediate feedback and reduce handling errors. Uncertainty analysis ensures measurement system capability.

Continuous Improvement in Tolerance Control

Systematic improvement programs reduce variation and improve process capability over time. Continuous improvement focuses resources on the most significant sources of variation and quality problems.

Process capability studies quantify the ability of swiss precision machining to produce parts within limits. Capability indices provide numerical measures of process performance and identify processes requiring improvement. Regular capability analysis tracks improvement progress.

Design of experiments identifies process parameters that most significantly affect dimensional accuracy. DOE methodology optimizes process settings to minimize variation and improve capability. Experimental approaches provide scientific basis for process improvement.

Lean manufacturing principles eliminate waste and improve consistency in manufacturing processes. Standardized procedures, visual management, and error-proofing techniques reduce variation and improve quality. Lean methods focus on value-added activities and eliminate non-value activities.

Six Sigma and Lean manufacturing principles further eliminate waste and improve consistency, ensuring that every swiss CNC machine in the facility operates at peak efficiency. DMAIC problem-solving methodology systematically analyzes problems and implements solutions. Six Sigma tools help achieve breakthrough improvements in quality and capability.

Predictive maintenance programs prevent equipment degradation that affects dimensional accuracy. Vibration monitoring, thermal imaging, and oil analysis identify developing problems before they affect quality. Predictive maintenance maintains process capability and prevents quality problems.

Contact our precision manufacturing specialists today to develop tolerance control strategies that ensure consistent quality and reduce manufacturing costs.

Industry Standards and Technical Resources

Professional precision manufacturing follows established industry standards that ensure consistent quality and measurement practices. The American Society of Mechanical Engineers develops standards for geometric dimensioning and tolerancing that provide systematic approaches to tolerance specification and verification.

The National Institute of Standards and Technology establishes measurement standards and calibration procedures that ensure measurement accuracy and traceability throughout the manufacturing industry.

Frequently Asked Questions

How do tolerance stack up problems affect assembly costs and production schedules?

Tolerance stack up problems significantly increase assembly costs through rework, selective assembly, and production delays. Prevention through proper tolerance analysis and the use of a qualified swiss machine shop eliminates these costs and maintains predictable production schedules. Selective assembly processes sort components into matched sets, increasing inventory costs and complicating production scheduling. Rework operations to modify components add labor costs and extend production timelines. Quality failures discovered during assembly or testing require extensive investigation and corrective action that disrupts production schedules. Prevention through proper tolerance analysis and process control eliminates these costs and maintains predictable production schedules.

What manufacturing processes provide the best capability for maintaining tight tolerances? Swiss machining, precision grinding, and multi-axis machining centers provide the best capability for maintaining tight tolerances in production environments. A swiss CNC machine excels at producing small, complex parts with tolerances within ±0.0001 inches through excellent rigidity and thermal stability. Precision grinding achieves tolerances within ±0.00005 inches on critical surfaces through controlled material removal and excellent surface finish. Multi-axis machining centers maintain tight tolerances by eliminating setup errors and maintaining consistent tool-to-work relationships. In-process measurement and adaptive control systems further improve capability by providing real-time feedback and correction. Process selection depends on part geometry, material, and production volume requirements.

How do material properties affect dimensional stability and tolerance control? Material properties significantly affect dimensional stability through thermal expansion, internal stress, and machining behavior. Materials with high thermal expansion coefficients require temperature control during machining and measurement to maintain dimensional accuracy. Internal stress in materials causes distortion when stress is relieved during machining, affecting dimensional stability. Hardness variations change cutting forces and tool wear rates, affecting machining consistency. Metallurgical condition affects machining behavior and may cause dimensional variations between material lots. Material selection, stress relief procedures, and process optimization help control material-related variation. Consistent material properties from qualified suppliers ensure predictable machining behavior and dimensional control.

What measurement system requirements ensure accurate tolerance verification? Measurement systems must have resolution, accuracy, and repeatability adequate for the tolerances being verified. The general rule requires measurement uncertainty less than 10% of the tolerance being measured, though critical applications may require 5% or better. Coordinate measuring machines provide the most comprehensive capability for complex parts with multiple features and geometric tolerances. Environmental control maintains stable temperature and reduces measurement uncertainty from thermal effects. Regular calibration and measurement system analysis verify continued capability and identify degradation. Proper measurement procedures and operator training ensure consistent and accurate results. Statistical analysis of measurement data helps identify measurement system problems and process variations.

How can manufacturers optimize tolerance allocation to balance function and cost? Tolerance optimization requires functional analysis to identify dimensions that actually affect assembly performance and customer requirements. Sensitivity analysis determines which component tolerances have the greatest impact on assembly function, allowing resources to focus on critical dimensions. Statistical tolerance analysis provides more realistic assessment of assembly variation than worst-case methods, enabling optimized tolerance allocation. Manufacturing cost analysis evaluates the cost impact of different tolerance requirements and identifies opportunities for relaxation without affecting function. Design for manufacturing principles suggest design modifications that maintain function while improving manufacturability. Collaboration between design and manufacturing teams ensures that tolerance requirements reflect both functional needs and manufacturing capability.