Precision Testing Services | Component Validation & Quality Verification

Shamrock Precision delivers professional and reliable precision testing services for manufacturers who need real validation before components go into service. We've spent over 40 years tirelessly learning what quality verification means across aerospace, medical, oil & gas, and energy sectors.

Manufacturing quality and reliability depend on accurate testing. Searching and locating defects early saves money and prevents field failures that cost thousands in downtime and repairs. At our precision testing center, we provide:

- Dimensional testing for complex geometries and tight tolerances

- Materials testing services across standard and exotic alloys

- Functional testing that simulates real operating conditions

- Complete documentation meeting industry certification requirements

- Fast turnaround times that keep production schedules on track

Why Precision Testing Actually Protects Your Operations

Component failures can cost serious money and waste an enormous amount of time. A single failed part can shut down an entire production line or create safety hazards. Appropriate and regular precision testing services catch problems before installation, when fixing issues costs pennies compared to field repairs. Simply put, unplanned downtime can be detrimental to your facility’s production schedule. Not to mention, this creates customer service nightmares.

- CMM equipment measures features down to 0.0001 inches on complex shapes

- Comprehensive materials testing services validate strength, hardness, and mechanical properties

- Functional testing proves components work under actual operating conditions

- Pressure testing checks seal integrity up to 10,000 PSI

- Environmental testing shows how parts handle temperature extremes

According to the Bureau of Labor Statistics, manufacturing inspection and testing jobs require specialized skills and technical knowledge that protect production operations.

How We Handle All Testing Our Projects

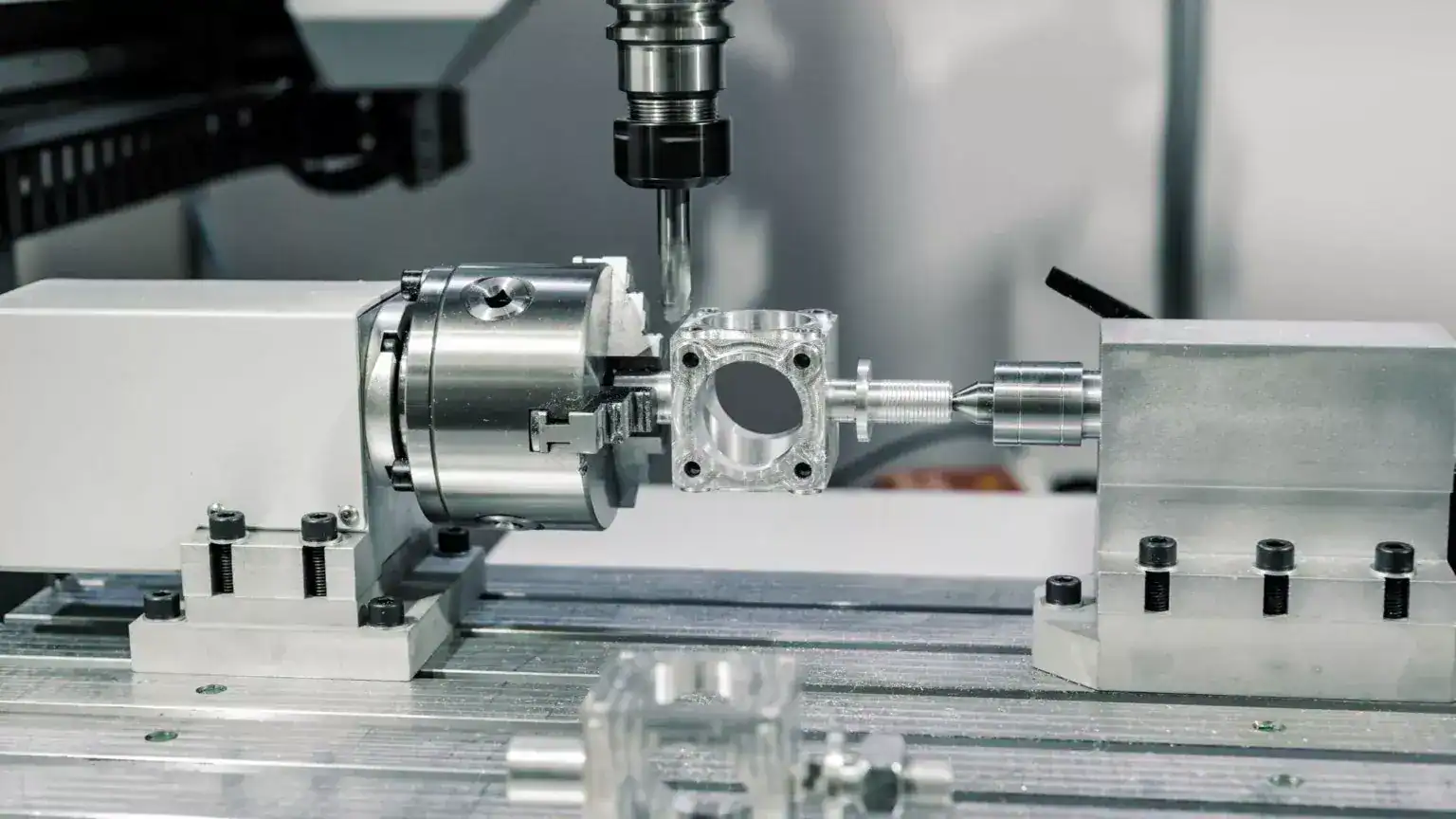

All our testing projects at the precision testing center start with understanding what needs verification and why. We carefully and meticulously review specifications and identify critical features requiring measurement. Our climate controlled facility maintains consistent temperatures because metal dimensions change with heat.

- Our Initial review carefully examines drawings to determine precision testing requirements

- The equipment selection process chooses measurement tools, including specialized CMM equipment, based on part geometry

- Our rigorous testing protocols follow step by step procedures matching industry standards

- Measurement execution uses calibrated equipment and trained technicians

- We generate documentation that provides detailed reports with actual measurements

- Our final meticulous review verifies all requirements met before releasing components

Complete Testing Capabilities We Offer

Our innovative and thorough testing department handles dimensional, material, and functional validation. Our aerospace customers need and expect AS9100 documentation with full traceability, our medical device manufacturers require material certifications, and our oil & gas companies want pressure testing and environmental validation. We customize our precision testing approach depending on the customer and sector.

Dimensional Testing:

- CMM equipment inspection for complex three-dimensional parts

- Optical comparators work for profiles and small features

- Surface finish measurement and verification

- Thread inspection for precision fasteners

- Geometric dimensioning and tolerancing validation

Material Property Testing:

- Hardness testing on Rockwell and Brinell scales

- Tensile strength and yield point verification

- Chemical composition analysis for alloy confirmation

- Grain structure examination for heat treatment validation

Functional Performance Testing:

- Pressure testing for seals and fittings

- Torque testing for fasteners and threaded components

- Environmental chamber testing from negative 40°F to 500°F

- Salt spray testing for corrosion resistance validation

Need help with heat treating, plating, or other secondary operations? Our outside process management services coordinate everything with approved vendors.

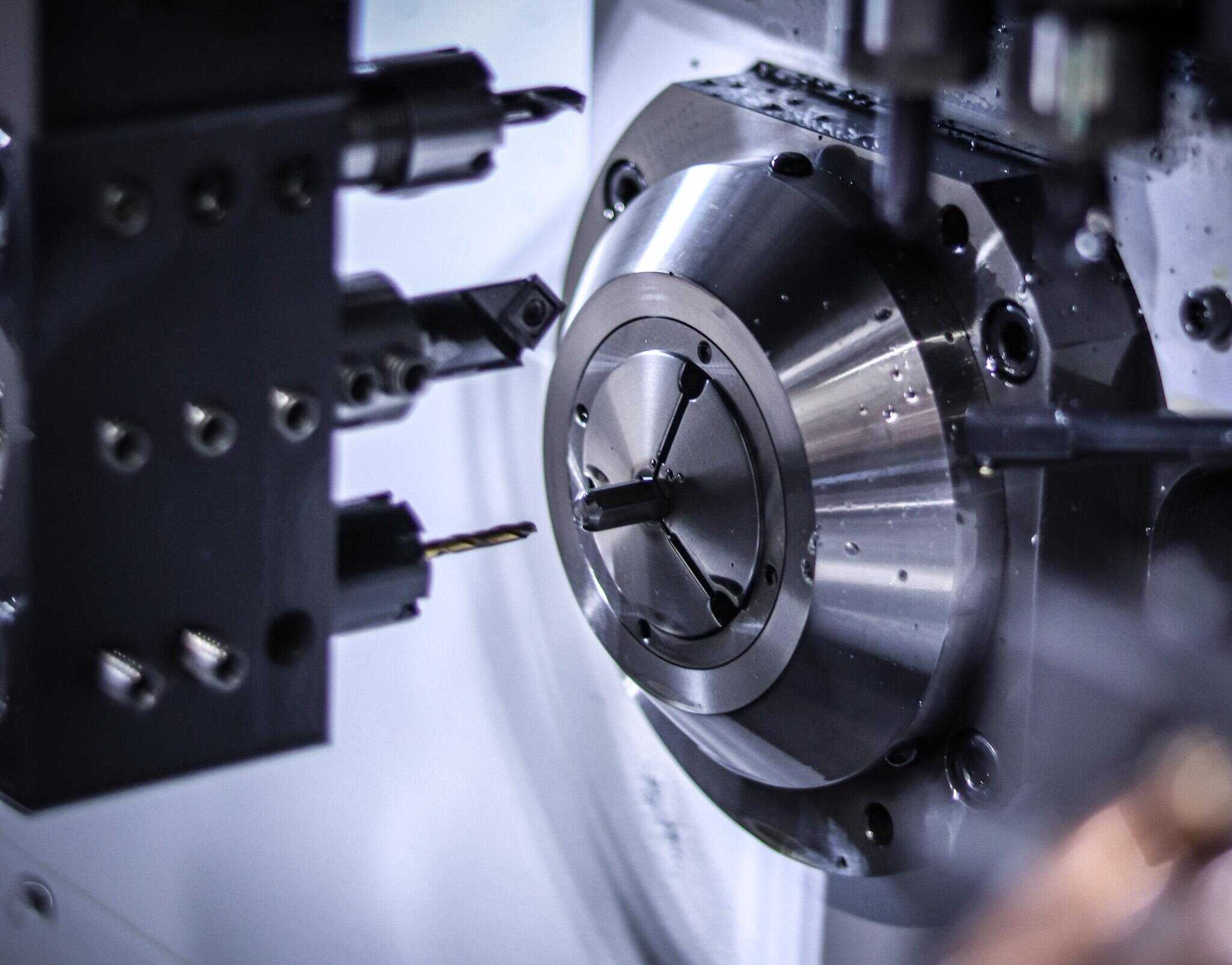

Testing Equipment We Run Daily

Good precision testing requires proper equipment maintained in excellent condition. Our precision testing center runs multiple measurement systems covering different part sizes and accuracy requirements.

- CMM equipment handles parts up to 24 inches with accuracy to 0.0001 inches

- Optical comparators magnify part profiles up to 50x

- Material testing services include portable and bench hardness testers

- Tensile testing equipment measures yield and ultimate strength

- Environmental chambers cycle between temperature extremes

- Pressure testing rigs handle hydraulic and pneumatic components

Materials and Components We Test

Our precision testing services cover materials from basic carbon steel to exotic aerospace superalloys. Different materials require different testing approaches because aluminum behaves differently from titanium.

- Aerospace parts requiring AS9100 documentation and material traceability

- Medical device components with biocompatibility requirements

- Oil & gas equipment is facing high pressure and corrosive environments

- Energy sector components handling extreme temperatures

- Part sizes range from tiny fasteners under 0.125 inches to large components over 24 inches

Industry Testing Standards and Data

Manufacturing quality standards keep getting tighter. The National Institute of Standards and Technology maintains measurement traceability standards that testing equipment must meet. Quality control costs money upfront but prevents expensive failures later. Quality cannot be shortchanged or understated. It is critical for project success.

- Our calibration certificates prove and record the CMM equipment's accuracy against known standards

- Catching defects during precision testing costs a whopping 10 times less than fixing field failures

- ISO 9001 certification requires stringent documented procedures and regular audits

- AS9100 adds aerospace-specific requirements for configuration control

What Makes Our Testing Services Different

Shamrock Precision combines advanced CMM equipment with decades of manufacturing knowledge. This is something you can rely on when you work with our team. Our technicians have machined thousands of parts, so they understand how features function and where problems hide within a precision testing center environment.

- Complete documentation packages with actual measurements

- Materials testing services certificates trace back to mill test reports

- Rush jobs get prioritized when production deadlines loom

- ISO 9001 and AS9100 certified quality systems

- Over 40 years serving aerospace, medical, and energy manufacturers

Quality costs less than failures. Our precision testing services verify components meet specifications before they reach your operations.