Shamrock Precision: Swiss Machining Excellence for Aerospace and Defense

Aircraft electrical systems interface with airframe structures through thousands of mounting components designed to secure wiring harnesses while accommodating thermal expansion, vibration, and maintenance access requirements that span decades of operational service. Mounting sleeves and inserts form critical connections between electrical protection systems and aircraft structures, demanding manufacturing precision that prevents loosening in service while enabling installation and removal during maintenance operations occurring throughout aircraft service life.

The mounting challenges in aerospace applications exceed those found in other industries by orders of magnitude that make general industrial hardware unsuitable for aviation service. Components must maintain secure attachment through temperature swings spanning hundreds of degrees between high-altitude cruise and ground operations in extreme climates, continuous vibration across multiple frequency ranges from engine harmonics to aerodynamic buffeting, and thousands of pressurization cycles throughout aircraft service life that stress every mechanical connection. Manufacturing tolerances that would suffice for industrial applications prove inadequate for aerospace mounting hardware where failure creates both safety risks and expensive unscheduled maintenance events requiring aircraft grounding.

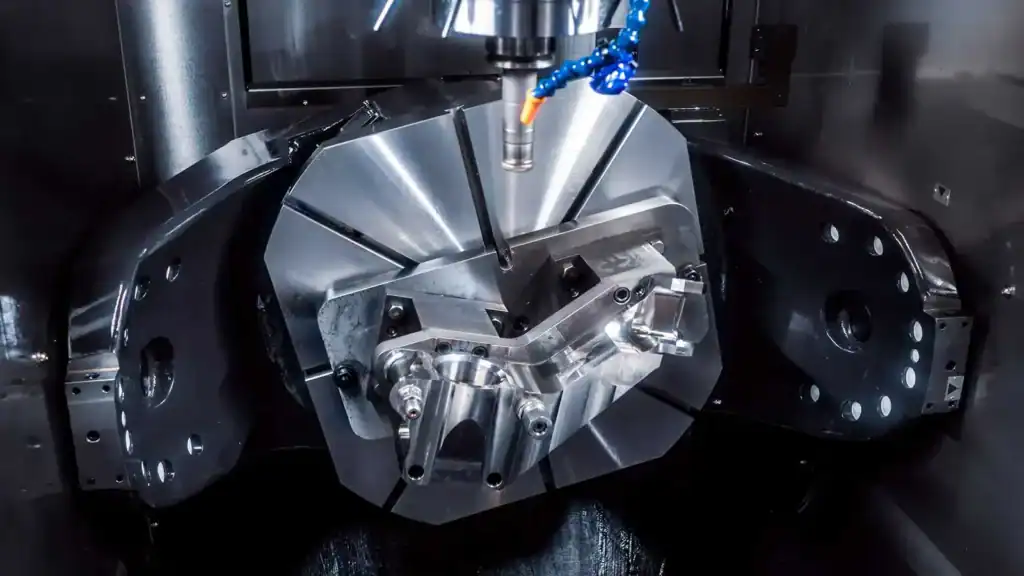

Inserts present particular manufacturing challenges requiring capabilities beyond conventional machining approaches. These components often feature complex internal thread forms designed for specific fastener engagement, precisely controlled outer diameters for interference or transition fits that secure inserts in structural holes, and specific surface finishes optimized for adhesive bonding or mechanical retention in composite structures increasingly common in modern aircraft designs. Swiss machining accommodates these multi-feature requirements in single operations, maintaining the geometric relationships between internal and external features that determine installed performance and long-term reliability.

According to the U.S. Bureau of Labor Statistics, employment of aerospace engineers is projected to grow 6 percent from 2024 to 2034, faster than the average for all occupations. The median annual wage for aerospace engineers reached $134,830 in May 2024, reflecting the specialized expertise required in this demanding field. About 4,500 openings for aerospace engineers are projected each year, with many resulting from the need to replace workers who transfer to different occupations or exit the labor force. Aircraft are being redesigned for less noise pollution and better fuel efficiency, which should help drive demand for aerospace professionals across the supply chain.

For mounting sleeve and insert manufacturing, technical expertise extends from process development through production and inspection stages where understanding component function guides manufacturing decisions affecting installed performance. Machinists must understand how dimensional variations affect fit and function in assembled aircraft structures. Quality personnel must recognize the critical characteristics that require enhanced verification beyond standard inspection protocols. This knowledge accumulates over years of aerospace production experience that cannot be replicated through equipment purchases alone.

Understanding the broader context of aerospace electrical component manufacturing helps procurement teams evaluate supplier capabilities holistically across related component families. Reviewing Aerospace Swiss Machining: Meeting Demand for Critical Electrical Components provides essential background on how Swiss machining technology supports production across multiple component families serving aircraft electrical systems in commercial and defense applications.

Mounting sleeves differ from inserts primarily in their function as intermediate components between wiring protection systems and structural mounting points throughout aircraft assemblies. These parts often feature stepped diameters transitioning between different interface requirements, specific length-to-diameter ratios requiring stable machining support to prevent deflection during material removal, and thread forms on one or both ends for connection to adjacent components. The concentricity between threaded and non-threaded sections determines whether assembled components align properly when installed, making this geometric relationship a critical quality characteristic requiring verified process capability through statistical analysis of production data.

Material requirements for mounting hardware depend on structural materials at installation locations throughout aircraft assemblies where galvanic compatibility and thermal expansion matching affect long-term reliability. Aluminum sleeves and inserts serve aluminum structures, avoiding galvanic corrosion concerns that accelerate degradation in aerospace environments while matching thermal expansion characteristics that prevent loosening through temperature cycling. Titanium mounting components support titanium structures in high-temperature regions including engine nacelles and auxiliary power unit compartments. Stainless steel hardware finds application where corrosion resistance takes priority over weight considerations in areas exposed to moisture and chemical contamination.

Each material demands specific machining approaches that Swiss equipment accommodates through programmable process parameters developed for particular alloy compositions. Cutting speeds, feed rates, depth of cut, coolant selection, and tooling materials all require optimization for specific materials to achieve the surface finishes and dimensional accuracy aerospace applications demand. This process knowledge represents intellectual property that experienced aerospace shops protect and refine through continuous improvement programs tracking quality data across production lots.

The Manufacturing Extension Partnership National Network delivers comprehensive solutions to U.S. manufacturers through a unique public-private partnership comprising the National Institute of Standards and Technology's MEP, 51 MEP Centers located in all 50 states and Puerto Rico, and over 1,440 trusted advisors at approximately 460 service locations. MEP Centers tailor services ranging from process improvement and workforce development to specialized business practices including supply chain integration and technology transfer, connecting manufacturers with government agencies, universities, research laboratories, and other resources essential for aerospace competitiveness.

Machine shops investing in Swiss machining technology partially address workforce constraints through automation capabilities enabling extended unattended operation that multiplies effective production capacity without proportional workforce increases. However, the technical expertise required for aerospace production programming, setup, first article inspection, and quality verification remains essential regardless of automation level. Shops must maintain skilled personnel who understand both machining fundamentals and aerospace-specific requirements that govern production decisions.

Quality documentation requirements for mounting sleeves and inserts trace back through material certification, process control, dimensional verification, and final acceptance in documentation packages that accompany every shipment. Aerospace customers increasingly require statistical process control data demonstrating manufacturing consistency across production lots through capability indices proving processes remain centered and controlled. First article inspection reports establish baseline capability that subsequent production must maintain through ongoing measurement and analysis. This documentation infrastructure distinguishes aerospace-qualified suppliers from shops simply claiming capability without the systems to prove performance.

Traceability requirements extend throughout aerospace component manufacturing in ways unfamiliar to general industrial production. Every mounting sleeve and insert must trace back to specific material lots with documented composition and properties. Production records must identify equipment, tooling, operators, and process parameters used during manufacturing. Inspection records must document measurement results with instrument identification and calibration status. This complete history enables investigation if components fail in service while providing confidence that delivered parts meet all requirements.

For aerospace teams evaluating specific component categories within electrical system manufacturing, examining Aerospace Sleeve Conduits: How Swiss Machining Protects Critical Wiring Systems reveals how Swiss machining capabilities address the unique requirements of conduit production where thin-wall tubular geometries present distinct manufacturing challenges requiring specialized approaches.

The combination of complex geometry, tight tolerances, material diversity, and documentation requirements makes mounting sleeve and insert manufacturing a demanding specialty within aerospace precision machining. Shops demonstrating consistent success across these component families through years of production experience establish themselves as valuable supply chain partners for programs prioritizing quality and delivery performance over lowest initial pricing that often proves false economy when quality problems emerge during production.

Shamrock Precision: Your Partner in Aerospace Manufacturing Excellence

At Shamrock Precision, we manufacture precision mounting sleeves and inserts supporting aerospace structural applications through AS9100-certified Swiss machining operations. Our team delivers the tolerances and documentation these critical components require for safe aircraft operation.

Our Services Include:

- Aerospace Machining Services - Swiss CNC production of mounting hardware with tolerances to ±0.0005 inches

- Contact Us - Discuss your mounting sleeve and insert manufacturing requirements

Works Cited

"Aerospace Engineers." Occupational Outlook Handbook, U.S. Bureau of Labor Statistics, 28 Aug. 2025, www.bls.gov/ooh/architecture-and-engineering/aerospace-engineers.htm. Accessed 1 Feb. 2026.

"Aerospace." Manufacturing.gov, National Institute of Standards and Technology, www.manufacturing.gov/topic/aerospace. Accessed 1 Feb. 2026.

Related Articles

- Aerospace Swiss Machining: Meeting Demand for Critical Electrical Components

- Aerospace Sleeve Conduits: How Swiss Machining Protects Critical Wiring Systems