- Home

- Products

- Precision Machining

High-Quality Precision Machining

Using our extensive multi-tasking CNC turning and CNC milling capabilities, in combination with lean manufacturing practices, we focus on providing quick-turn, precision manufacturing articles exact to your specifications.

Our ISO 9001 and AS9100 quality systems, coupled with ITAR compliance and controls, help ensure your information and parts are continually in good hands. Shamrock machines almost all metals, including Stainless Steel, Copper, Brass, Steel, Inconel, Beryllium Copper, Nickel Silver, Titanium, Zirconium, and other standard and specialty metals and alloys.

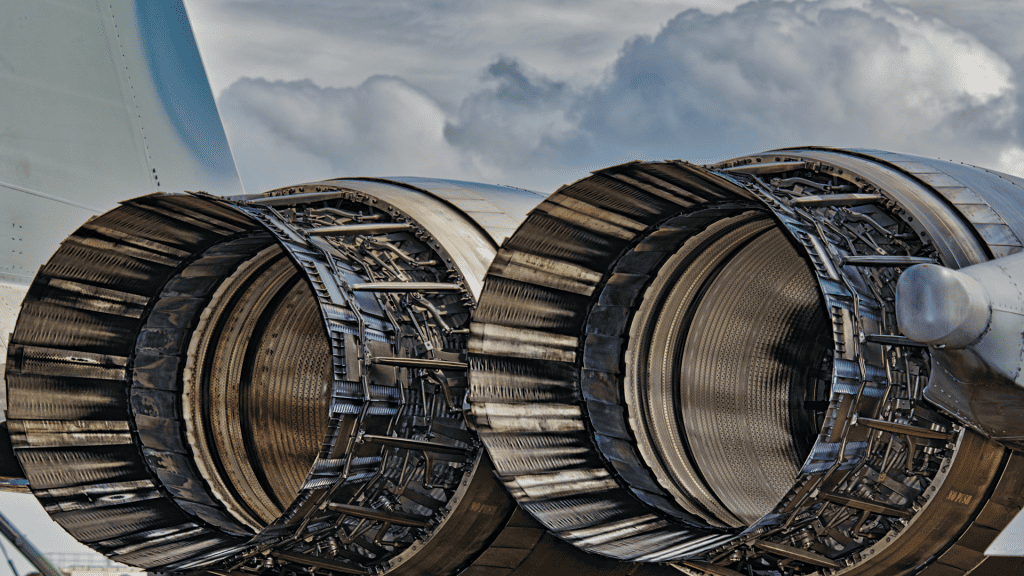

Aerospace Machining

Using our extensive multi-tasking CNC turning and milling capabilities, in combination with lean manufacturing practices, we focus on providing quick-turn, precision manufacturing articles exact to your specifications.

Our services include aerospace parts machining and machined aerospace products. At Shamrock Precision, we exercise a dual approach to the stratospheric material and process requirements of the aerospace industry. Shamrock Precision is ready, willing, and able to accept this unique challenge of crafting high-precision machining.

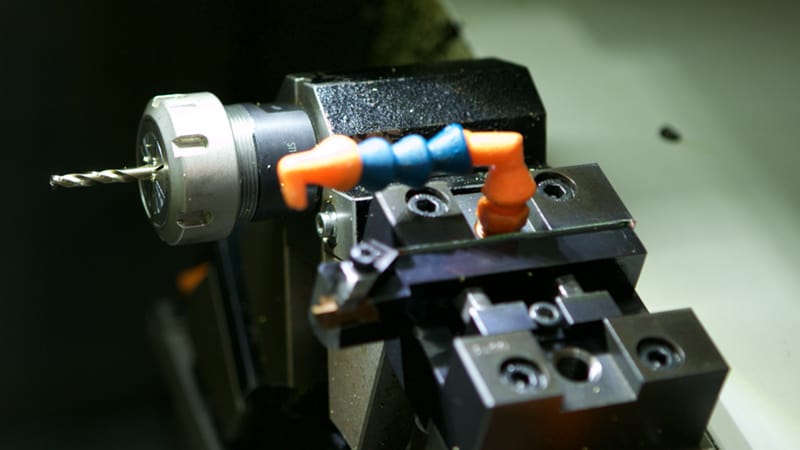

CNC Turning

Shamrock Precision’s high-performance turning centers are ready to take on your lathe job. With a capacity up to 21” in diameter, we have the resources and capabilities to meet your needs.

We offer the highest standard in CNC lathe machining and turning services. Our expert CNC programmers and machinists deliver accuracy, precision, and the highest quality in the industry. We offer:

- 4-axis milling/turning up to 8” diameter main spindle / 6” sub spindle

- 7-axis CNC lathes up to 18” Diameter

Turning Centers

Shamrock Precision invests in the latest equipment and technology to provide our customers with the highest quality components, parts, and services.

- (4) Mazak QT 100S > 1.625” Dia

- (2) Mazak QT Nexus 100M > 1.625” Dia

- (5) Mazak QT Nexus 250 > 8.00” Dia

- Okuma LB3000 MYW > 4-axis > 8.00” Main / 6.00” Sub

- Okuma Multus U3000 > 7-axis > 18.00” Dia

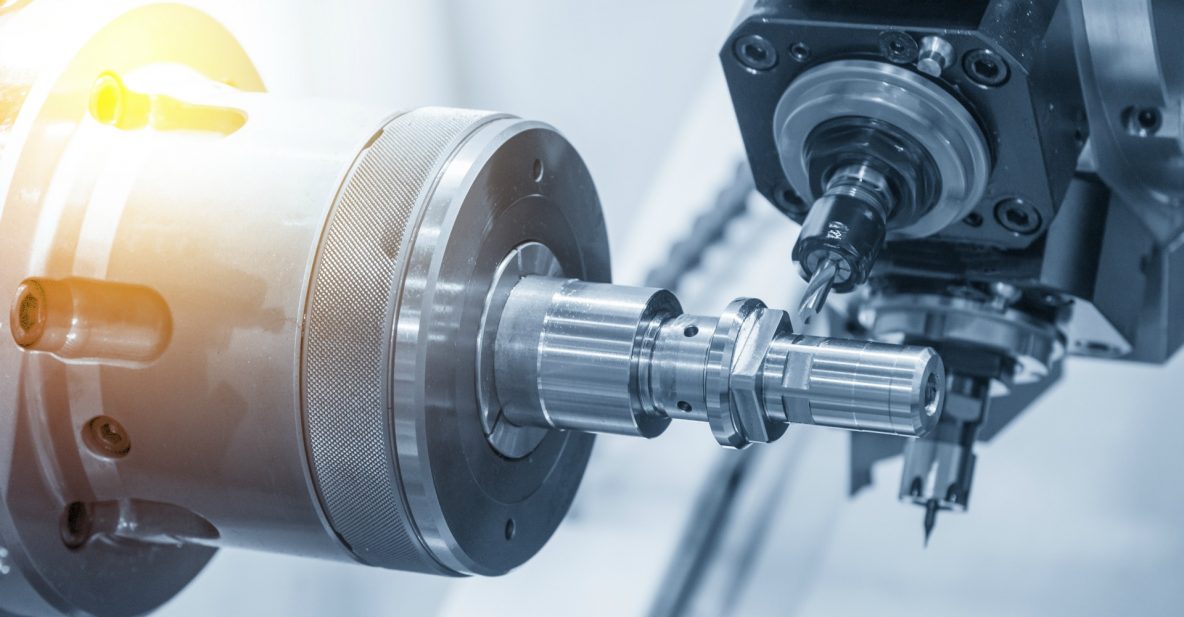

CNC Milling

Shamrock Precision provides 3, 4, and 5-axis CNC milling up to 24” x 30” x 24” for our customers in the energy, medical, electronic, aerospace, and defense industries.

3-Axis Milling

Shamrock Precision’s 3-axis machining center uses a cutting tool that moves along the X (Vertical), Y (Horizontal), and Z (Depth) axes to mill your part. Our 3-axis milling centers are best suited for milling basic contours, surfaces, and slots. They can also be used for drilling, tapping, reaming, and boring holes.

4-Axis Milling

Shamrock Precision’s 4-axis machining center executes the same functions as our 3-axis machining but with an added axis that allows for rotation around the Y-axis. This added feature on our horizontal mills allows for more complex shapes and sizes.

5-Axis Milling

Shamrock Precision’s 5-axis milling center significantly increases the range of possibilities for working with complex surfaces and creating parts in various shapes and sizes. Our 5-axis milling services deliver shorter lead times, greater accuracy, and longer tool life.

Milling Centers

Shamrock Precision invests in the latest equipment and technology to provide our customers with the highest quality components, parts, and services.

- Mazak Nexus 510C/50-II > 4-axis CAT50 > 20”x40”x24”

- Mazak VTC 20B > 4-axis CAT40 > 20”x40”x20”

- Makino A500Z > 5-axis > 24”x30”x24”

Ready to Get Started?

Discover how we can meet your product and pricing needs and still exceed your expectations. Get in touch with a member of our team today.

Why Choose Shamrock Precision for Precision Machining/Turning/Milling Services?

Shamrock Precision creates partnerships designed to increase productivity and reduce total costs for its customers. Our team of professionals provides machining/milling services at a competitive price that impacts the bottom line. Additional advantages of partnering with us include but are not limited to:

- Innovative and cost-effective solutions designed to increase productivity and save time and money.

- The highest quality engineers and machinists in the industry.

- Streamlined processes designed to provide expertise and short lead times.

- In-house capabilities providing full-service machining/milling services.

- Safe and green business practices are designed to support workplace and environmental safety.

Craftsmanship and Quality

To ensure the quality of our products, we source materials based on strict customer and industry standards. We work only with approved vendors. Our strong, long-standing relationships with these vendors allow us to operate more efficiently and effectively.

To achieve fast cycle times, we purposely invest in and maintain available capacity on critical equipment, tooling, and material. With an eye toward the future, we evaluate new trends, technology, and best practices available on the market. Shamrock Precision’s objective is to provide products which meet customer specifications, are delivered on time with continual improvement in our processes.

Industries We Serve

Shamrock Precision has a strong reputation and proven track record for providing the highest quality services for the energy, medical, electronic, aerospace, and defense industries. For more than three decades, our customers have trusted us to provide on-time delivery, quality products and innovative solutions.

Frequently Asked Questions

Machining is a process in which a material is cut to a desired final shape and size by a controlled material-removal process.

Custom CNC machining is a process that involves creating one-of-a-kind parts and components for various sectors such as the agricultural, automotive, and aerospace industries.

Turning is as a machining process where bars of metal are rotated while a tool is used to remove excess material until the desired shape is reached.

CNC milling (Computer Numerical Control Milling) is a machining process which utilizes computerized controls and rotating cutting tools to remove material from the workpiece to produce a specific product or part. This process is suitable for machining a wide range of materials, such as metal, plastic, glass, and wood, and producing a variety of custom-designed parts and products.

Multi-Axis Milling is a manufacturing process made up of tools moving in four or more directions used to manufacture parts out of metal or other materials by milling away excess material using water jet cutting or by laser cutting.

3 axis machining involves a workpiece in a fixed position while the cutting tool operates along the X, Y, Z plane to cut away material. 3-axis machining is most suitable for parts that do require a lot of depth and detailing.

4-axis machining adds movement of the cutting tool and allowing rotation around the X axis. As a result, there are 4 axes X, Y, Z and A rotating around the X axis. The majority of 4 axis CNC machine tools allow the workpiece to rotate, which is called b-axis, so the machine can act as both milling machine and lathe.

5-axis machines rely on a tool that moves in five different axes, the X, Y, and Z, as well as A and B, around which the tool rotates. Using a 5-axis CNC machine lets operators approach a workpiece all directions in a single operation without having to adjust the part.