- Home

- Products

- Testing & Inspection

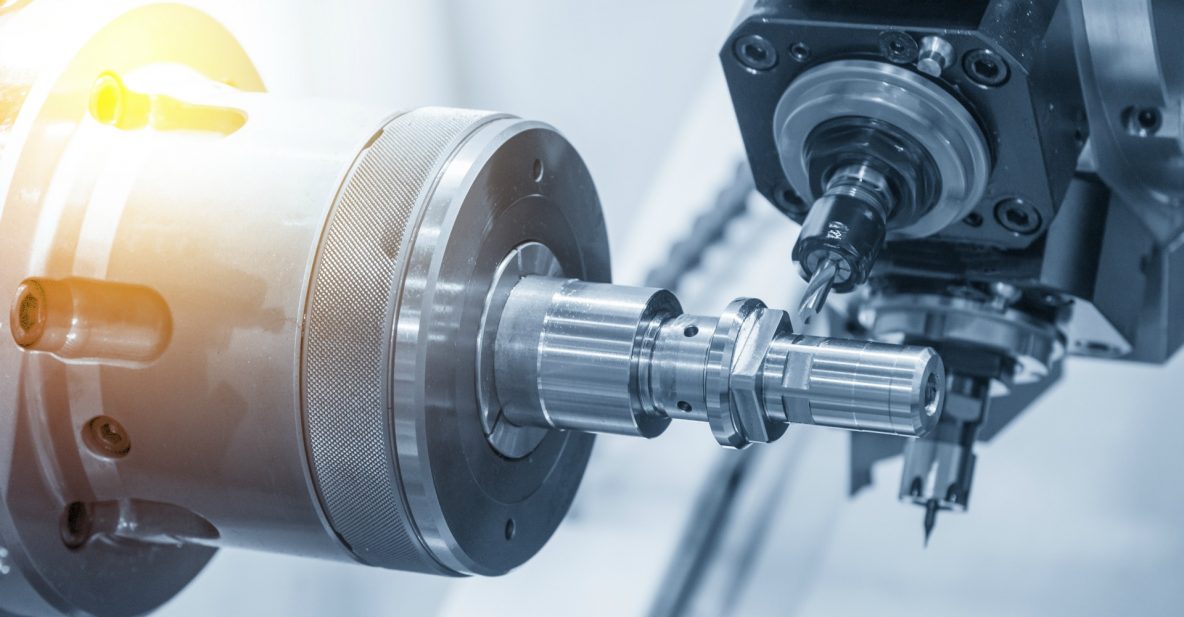

Testing & Inspection

Shamrock Precision uses proven technology to craft products with challenging dimensions, tight tolerances and short lead times job after job, year after year.

Shear Screws & Testing

Shamrock Precision is a leading supplier of shear screws and shear testing worldwide to our customer’s requirements. Including, but not limited to, Aerospace Standard NASM 1312-13 and NASM 1312-20 as well as customer-defined methods.

Quality Inspection & Equipment

Our customers demand quality parts delivered ON TIME. Shamrock Precision employs a robust MRP system (Global Shop Solutions) and the latest in inspection tool technologies to ensure quality and delivery are being met.

- Brown & Sharpe Global CNC CMM

- (2) S-T 20-3700 W/M2 Optical Comparator

- S-T 20-1600 W/M2 Optical Comparator

- (3) Keyence High Accuracy Measurement System

- (2) Clark CR-1 Hardness Testers

- Oasis High Accuracy Measurement System w/ Cobot Automation

Light Assembly

Shamrock Precision operates a modern facility with over 36,000 square feet of assembly space and can manage projects from start to finish. The company’s expert team handles riveting and thermal press fitting light assembly projects.

Ready to Get Started?

Discover how we can meet your product and pricing needs and still exceed your expectations. Get in touch with a member of our team today.

Why Choose Shamrock Precision for Testing & Inspection Services?

Shamrock Precision creates partnerships designed to increase productivity and reduce total costs for its customers. Our team of professionals provides testing & inspection services at a competitive price that impacts the bottom line. Additional advantages of partnering with us include but are not limited to:

- Innovative and cost-effective solutions designed to increase productivity and save time and money.

- The highest quality engineers and machinist in the industry.

- Streamlined processes designed to provide expertise and short lead times.

- In-house capabilities providing testing and inspection services.

- Safe and green business practices designed to support workplace and environmental safety.

Craftsmanship and Quality

To ensure the quality of our products, we source materials based on strict customer and industry standards. We work only with approved vendors. Our strong, long-standing relationships with these vendors allow us to operate more efficiently and effectively.

To achieve fast cycle times, we purposely invest in and maintain available capacity on critical equipment, tooling, and material. With an eye toward the future, we evaluate new trends, technology, and best practices available on the market. Shamrock Precision’s objective is to provide products which meet customer specifications, are delivered on time with continual improvement in our processes.

Industries We Serve

Shamrock Precision has a strong reputation and proven track record for providing the highest quality services for the energy, medical, electronic, aerospace, and defense industries. For more than three decades, our customers have trusted us to provide on-time delivery, quality products and innovative solutions.

Frequently Asked Questions

A shear test is designed to apply stress to a test sample so that it experiences a sliding failure along a plane that is parallel to the forces applied.

A coordinate measuring machine (CMM) is a piece of equipment that measures the geometries of physical objects. CMMs using a probing system to detect discreet points on the surfaces of objects.

Light Assembly is an operation that gives for a limited range of low intensity assembly activities including creating, repairing, or renovating products inside a fully enclosed building with minimum external effects.