In the intricate dance of manufacturing, precision machining takes center stage, shaping the components that are the backbone of various sectors. This blog dives into the profound impact of precision machining on different industries, exploring how this meticulous process influences the functionality, efficiency, and innovation in the creation of vital components.

Introduction

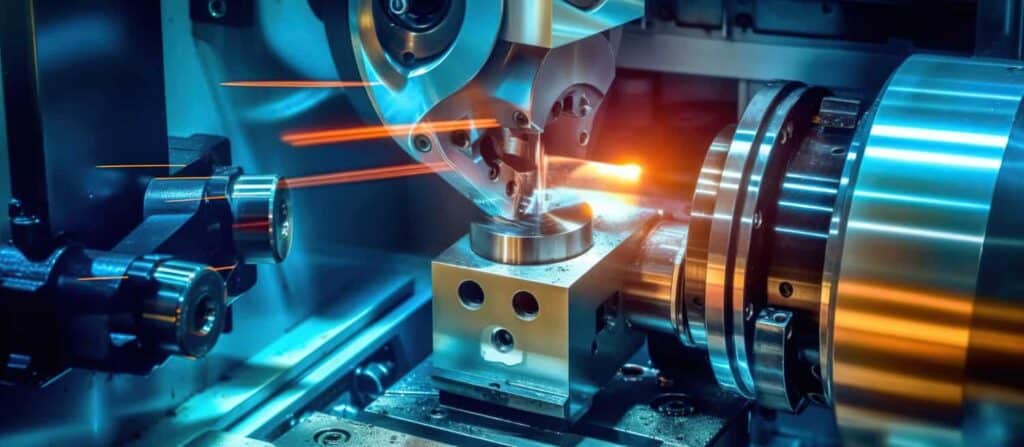

1. The Essence of Precision Machining

Precision machining is not merely a manufacturing process; it's an art form that involves crafting intricate components with exacting specifications. From aerospace to healthcare, precision machining plays a pivotal role in producing components that meet stringent standards, ensuring reliability and performance.

2. Beyond Manufacturing: A Journey Through Sectors

This exploration goes beyond the traditional confines of manufacturing, shedding light on how precision machining reverberates through diverse sectors, influencing the design and functionality of components that matter.

Aerospace Marvels

1. Crafting Components for the Skies

In the aerospace sector, precision machining reaches new heights—quite literally. Components for aircraft demand unparalleled precision to ensure safety and performance. From turbine blades to intricate structural elements, the aerospace industry relies on precision machining to create components that withstand extreme conditions.

2. Balancing Act: Lightweight Components

Precision machining enables the creation of lightweight components in aerospace engineering. By carefully sculpting materials with intricate geometries, manufacturers can reduce weight without compromising structural integrity, contributing to fuel efficiency and overall performance.

Medical Precision Unleashed

1. The Crucial Role in Medical Devices

Precision machining is a cornerstone in the production of medical devices. From orthopedic implants to surgical instruments, the medical industry depends on components crafted with precision to ensure compatibility, reliability, and biocompatibility.

2. Customization for Individual Needs

In medical manufacturing, one size does not fit all. Precision machining allows for the customization of components to meet the unique needs of patients. Implants tailored to specific anatomies or specialized surgical tools are made possible through the meticulous process of precision machining.

Automotive Engineering Prowess

1. Beyond Aesthetics: Precision in Automotive Components

Precision machining in the automotive sector goes beyond aesthetics; it's about performance and safety. Engine components, transmission parts, and intricate systems rely on precision machining to meet exact specifications, contributing to the overall reliability and efficiency of vehicles.

2. Innovations in Electric Vehicles

As the automotive industry transitions towards electric vehicles, precision machining plays a crucial role in crafting components for battery systems and electric drivetrains. The demand for precision is heightened as these components must meet stringent standards for safety and energy efficiency.

Technology's Playground: Electronics

1. Microscopic Precision for Electronic Components

In the realm of electronics, where miniaturization is paramount, precision machining takes on a microscopic scale. From microchips to intricate connectors, precision machining ensures the production of components that power our devices and enable technological advancements.

2. Keeping Pace with Technological Evolution

As technology evolves, so do the demands on electronic components. Precision machining allows for the production of components with intricate features, meeting the requirements of emerging technologies such as 5G, IoT, and artificial intelligence.

Energy Sector: Powering the Future

1. Precision Components for Energy Production

The energy sector relies on precision machining for the creation of components that power the world. From turbine components in power plants to intricate parts in renewable energy systems, precision machining ensures efficiency and reliability in energy production.

2. Sustainable Precision: Components for Renewables

In the pursuit of sustainability, precision machining contributes to the production of components for renewable energy systems. From wind turbine components to solar panel brackets, precision machining plays a role in advancing green energy solutions.

Defense and National Security

1. Military-Grade Precision

In the defense sector, precision machining takes on a military-grade significance. Components for defense systems, firearms, and aerospace applications demand the highest levels of precision to ensure reliability and performance in critical situations.

2. National Security Relies on Precision

Precision machining is a linchpin in ensuring national security. Components for communication systems, surveillance equipment, and advanced weaponry require meticulous craftsmanship to meet the exacting standards of defense applications.

Challenges and Innovations in Precision Machining

1. Materials Mastery

Precision machining often involves working with a diverse range of materials, each with its own challenges. Innovations in tooling and machining techniques continuously address the complexities of working with materials like titanium, composites, and high-temperature alloys.

2. Tolerances and Tight Specifications

Meeting tight tolerances and specifications is a constant challenge in precision machining. Advancements in machining technology and the use of advanced metrology tools help address these challenges, ensuring the consistent production of components with high precision.

The Future of Precision Machining

1. Advanced Materials and Techniques

The future of precision machining holds promise with the development of advanced materials and machining techniques. From nanomaterials to novel tooling technologies, precision machining is poised to evolve, opening new possibilities in component design and functionality.

2. Integration with Industry 4.0

As the fourth industrial revolution unfolds, precision machining integrates with Industry 4.0 principles. Automation, real-time monitoring, and data analytics enhance efficiency and quality control in precision machining processes, shaping the future of component manufacturing.

Conclusion

Precision Machining: A Silent Force Across Industries

In the world of manufacturing, precision machining stands as a silent force, shaping components that form the backbone of diverse sectors. From aerospace marvels to innovations in medical devices, the impact of precision machining resonates across industries, contributing to advancements that touch every aspect of our lives.

Crafting Tomorrow's Components

As technology advances and industries evolve, precision machining continues to play a pivotal role in crafting tomorrow's components. The meticulous process ensures that the components that matter meet the highest standards of quality, reliability, and innovation.